I've read numerous posts online about Kahr's being picky about what ammo they will chamber and wont due to their tight chambers. I want to share what I found with mine tonight after I locked it up tight today on it's first trip to the range while attempting to chamber one of my target loads after 100rds of Remington factory ball ammo.

I pulled the barrel out for cleaning tonight and attempted to chamber some various ammo by dropping them in while holding the barrel. I found some dropped right in while others stopped short of fully chambering. This is easier than trying to pry my action open like I had to do at the range today I found that hollow points with a pronounced shoulder on them like Hornady XTP's and the Nosler Custom Competition 185's that I love to load so much for my other 45's were what caused the problem.

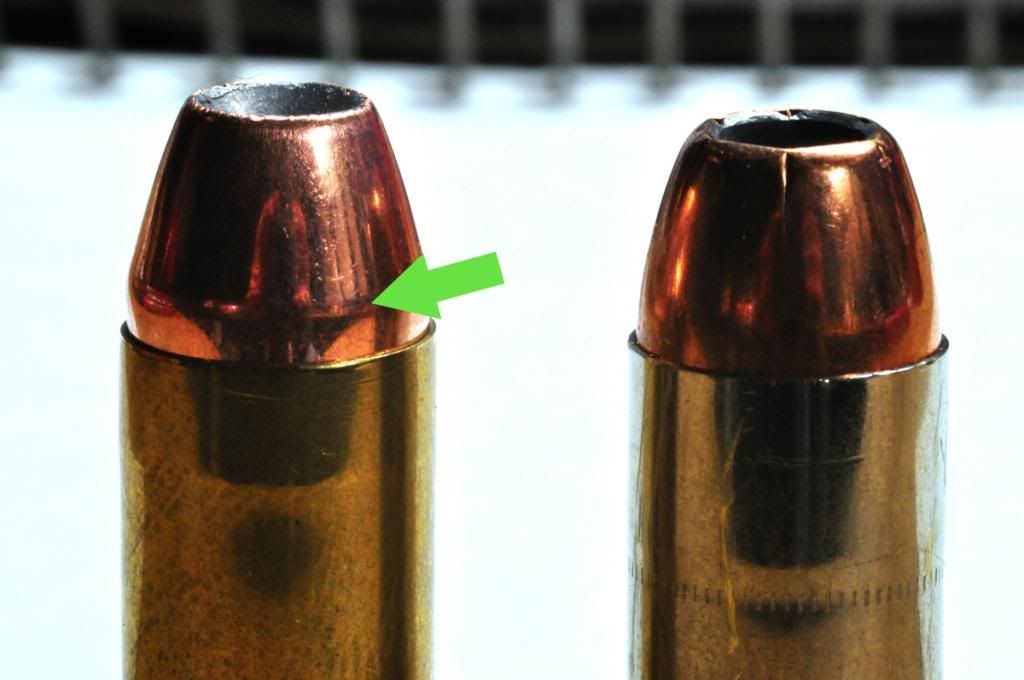

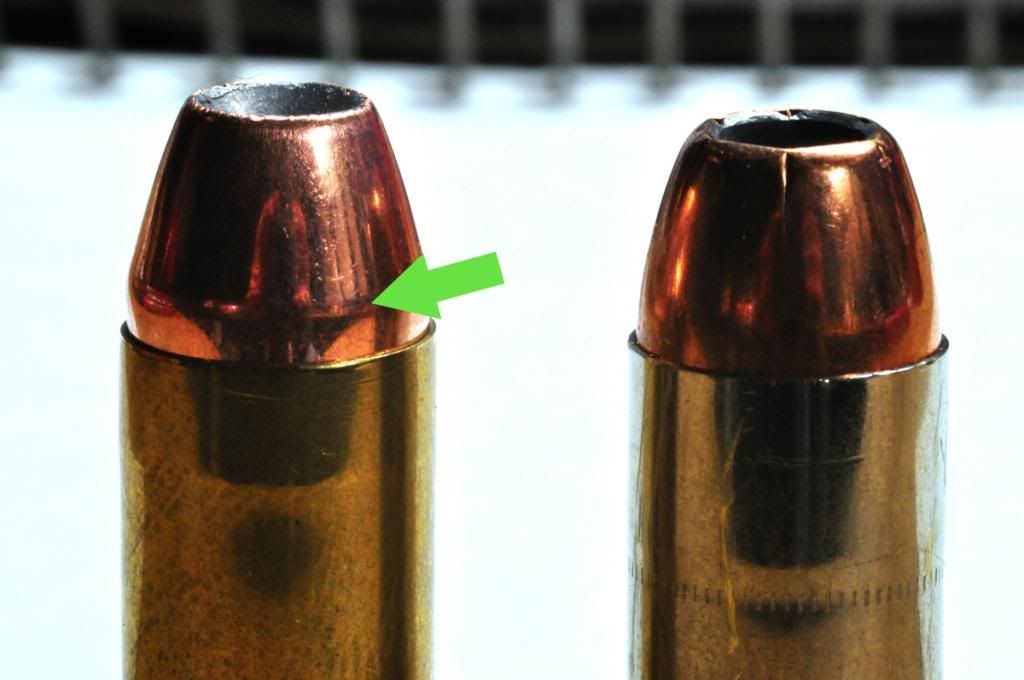

I took one that wouldnt chamber and dropped it in until it stopped and then grabbed the base of the shell with my fingers and twisted it back and forth about 90 deg while light pressing forward and pulled it out. The barrel is steel, the bullet jacket and shell case are soft metals so I knew the barrel/chamber should leave marks on the cartridge where it is hanging up. It was on the shoulder of the bullet as pictured below. On the left is a Nosler 185 handload and on the right is a Federal HydraShok. The Hydrashok drops right in, the Nosler does not... notice the difference in profiles close to the case mouth. The Hydrashok has a profile very similar to ball ammo until the top, so it chambers.

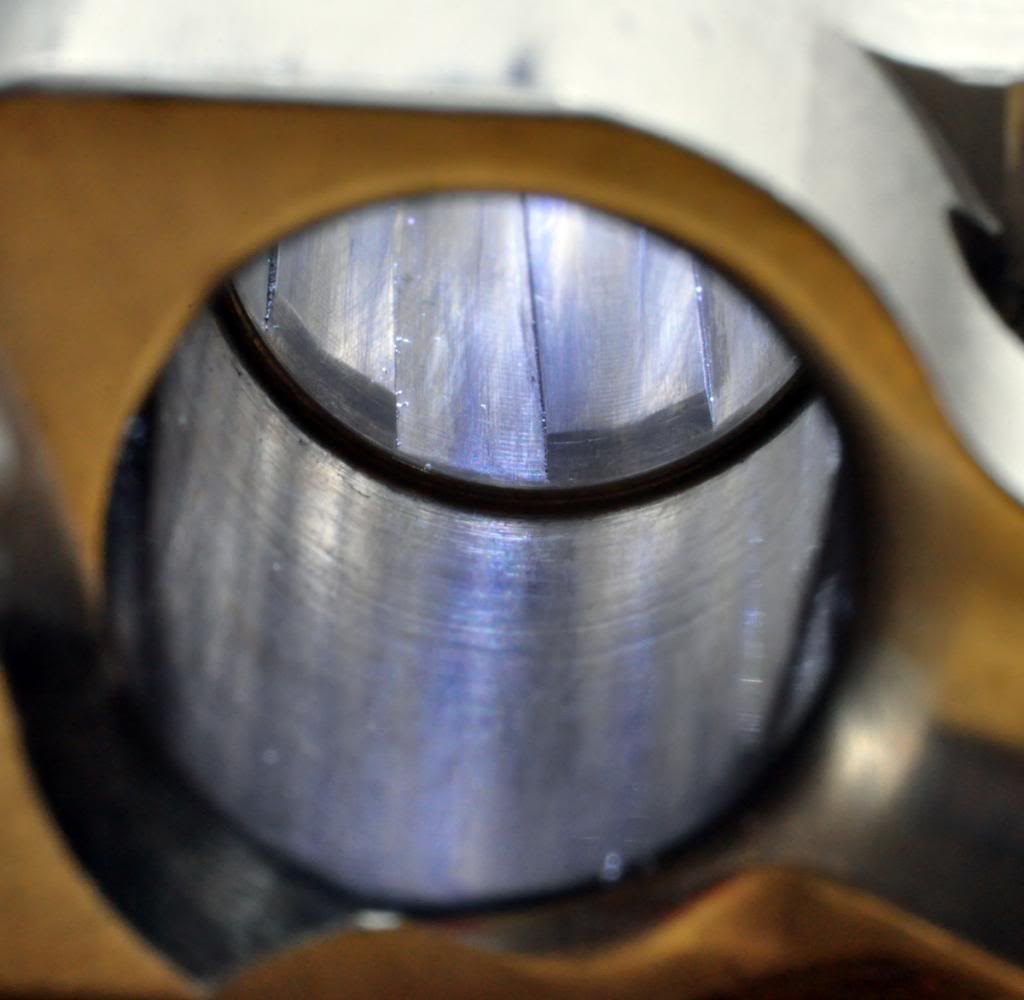

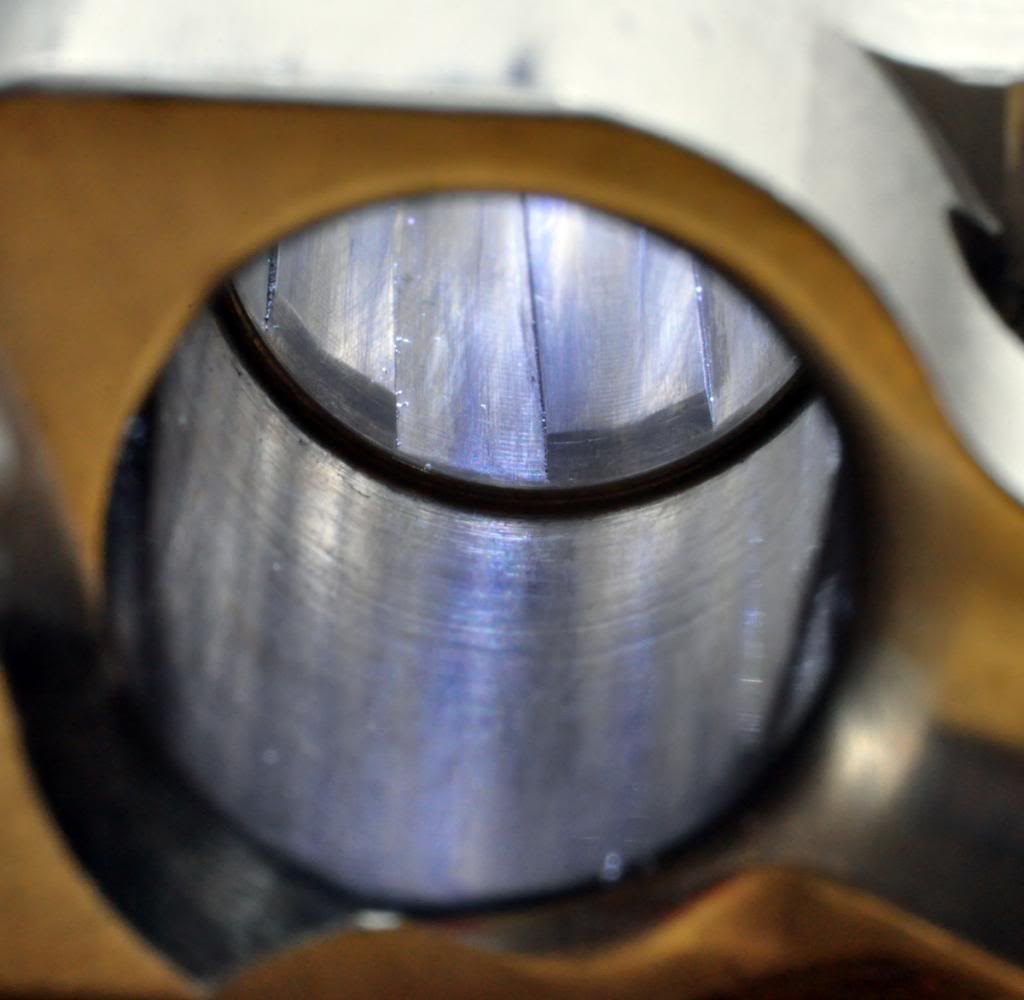

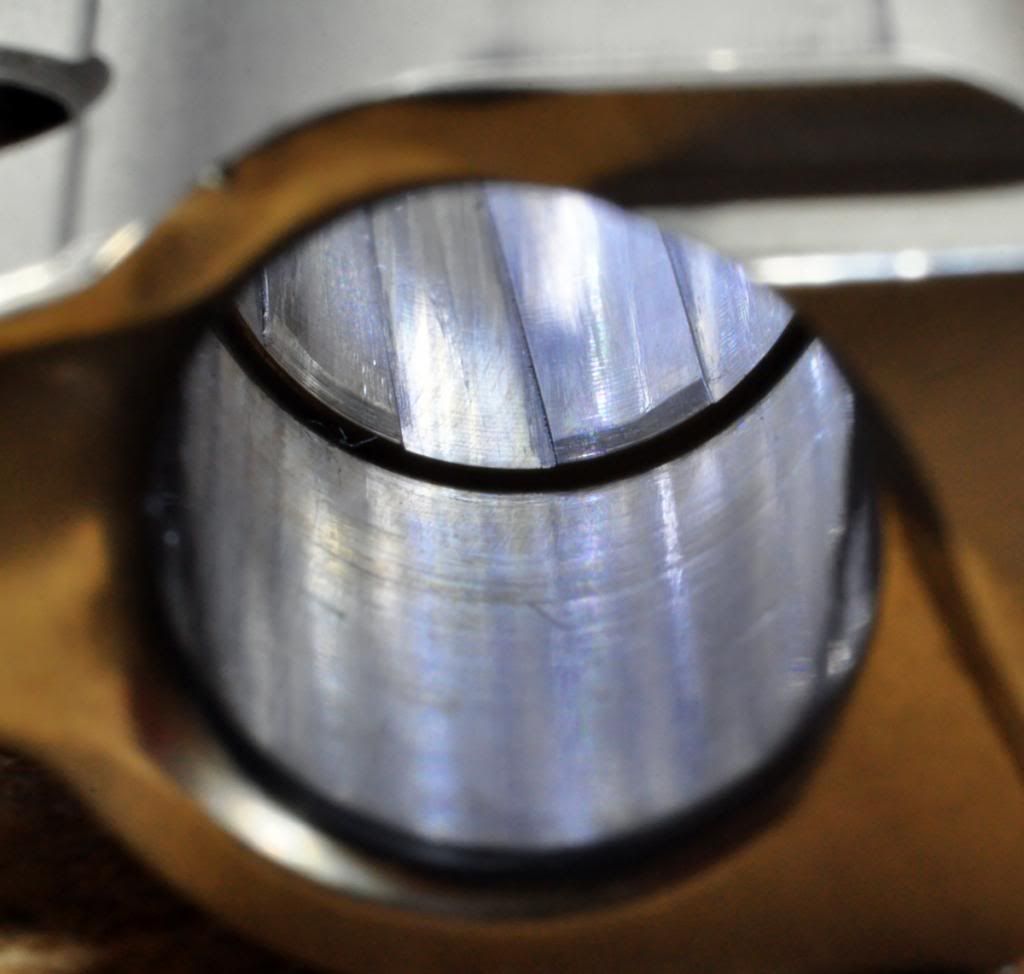

Because the marks from me twisting the cartridge in the chamber are on the bullet and not the casing, I started to look at the barrel and not the chamber. The chamber is no tighter than than my other 45's just by feeling the amount of freeplay with a cartdridge fully chambered. Pictured below is the lead-in to the rifling in my barrel.

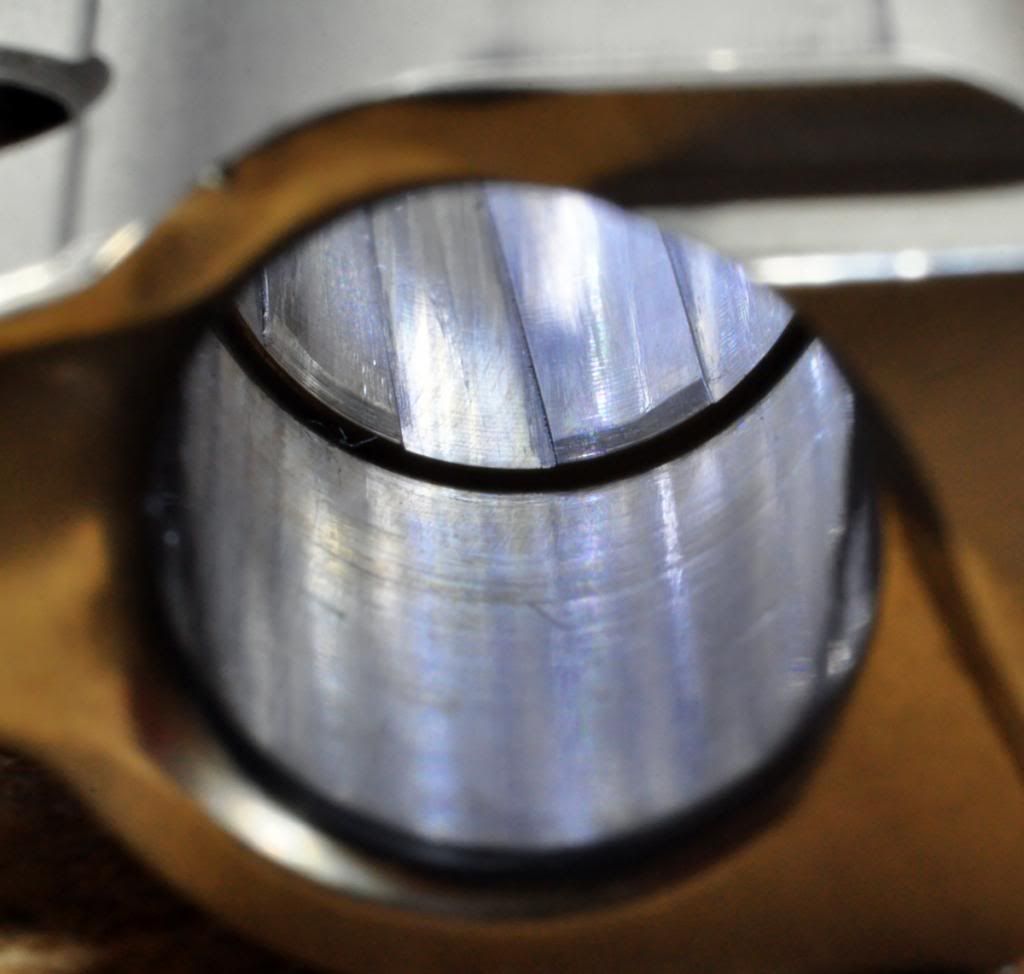

It is a steeper angle than my other 45's, but not that much different... why is it touching the bullet before the cartridge is fully chambered I wondered? As Im staring at it scratching my head I noticed that the lead-in is not uniform. Pictured above is the left side of my barrel, pictured below is the right side of my barrel. Notice the difference in the angle of the bevel on the beginning of the rifling.

THIS is why it will not chamber the bullets with a more pronounced shoulder profile. Is this considered defective? Normal? I dont know, this is my first Kahr. Perhaps some of you could take a look and see if your picky eater looks like this? I could get around this by changing the bullet seating depth of my target loads to work with this gun so Im not terribly concerned about it myself at this point. I did however want to share my findings because I've read a fair amount about folks having picky eaters that wont chamber certain types of ammo. Many of the threads on various forums/reviews seem to have the XTP style bullet causing the problems.

Brian

Reply With Quote

Reply With Quote